Careers in Manufacturing & Off-Site Production: Trade Skills Mobility, Lean Thinking, and Modern Methods of Construction (MMC)

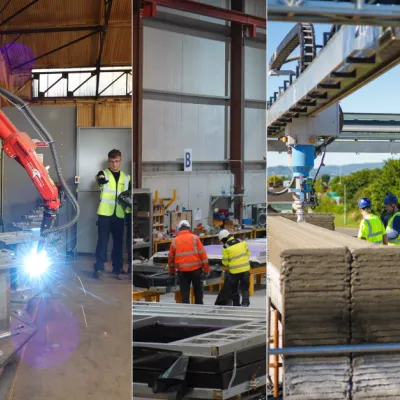

MMC can offer those who work in the construction sector and those new to the sector more opportunities in innovative job roles with a greater potential for work-life balance. Learn from the experiences of three people working in advanced manufacturing and off-site construction who are embracing the opportunities MMC has to offer in their own career journey.

Modern Methods of Construction (MMC) offer solutions for building projects across multiple industries and development processes. MMC also provides construction companies, and the individuals in them, with opportunities for skills development that can lead to innovative construction roles with a better work-life balance.

To maximise upskilling opportunities and support companies and individuals to accelerate their MMC education, the Skillnet MMC Accelerate Platform signposts users to national courses related to MMC, digitalisation, lean construction principles, and sustainable building materials and practices. This free resource provides users with access, in one place, to the most in-demand building industry skills across digital construction, modular construction, advanced manufacturing, and beyond.

On the platform, users can also find indicative roles and career pathways in MMC to support them in planning the next stage of their career. Industry experts have identified 100+ roles at the heart of MMC and have shared how those working in construction, at any stage of their career, have multiple opportunities to upskill and progress in MMC. This can offer clarity to those in the industry or those considering moving into the industry who want to take positive steps to achieving a satisfactory work-life balance.

We spoke to three construction professionals working in manufacturing and off-site production to learn how they moved into the MMC space, the benefits of working in MMC operations, and their plans for upskilling and driving their future career growth.

Billy Murphy is a Steel Fabrication Technician for Irish modular balcony manufacturer Extreme Balconies. Before joining the company, Billy had worked in the construction sector in Ireland and overseas in Australia as a labourer and doing formwork. However, early on Billy decided he needed to be more proactive in his career development.

“I wanted to become more skilled, get some proper training behind me. So, I looked into apprenticeships and decided Extreme Balconies would be a fit.”

Steel Fabrication Technician, Extreme Balconies

He joined the company’s ‘Extreme Balconies Academy’, where he spent one evening each week learning about metal fabrication for modular manufacturing. The course, while mostly teaching technical skills, also saw the factory foreman offering practical tips for how to navigate an MMC facility. Simultaneously, Billy completed a range of programmes such as forklift training, manual handling, and health and safety training.

“The skills I’ve learned are really transferrable. I can work on any modular project. Beyond fabrication, I can read technical drawings and interpret them, and I do a lot of quality control on the floor. With everything I’ve learned, I would like to move into the design office, do more training in AutoCAD and Tekla. You don’t want to be on the floor forever; I want to work my way up the ladder.”

Steel Fabrication Technician, Extreme Balconies

Long term, Billy says that he wants to take everything he has learned (while continuing the continuous skills development of recent years) to open his own metal fabrication facility. MMC is truly integrated into this current skillsets and broader career ambitions.

Deivid Matesa is Supply Chain Coordinator for off-site construction firm Remagin Etex Ireland. It’s the latest step in a career that started at just 8 years’ old, with Deivid going to work with his father to watch him on building sites. These experiences inspired a dream Deivid has chased since.

From his first role in Ireland as a General Operative, Deivid’s natural aptitude for learning and passion for the building industry set him apart from his contemporaries.

“Because of my interest in construction during my school years and what I learned from my father, I showed an aptitude for reading technical drawings and could quickly pick up on how processes worked, meaning I could contribute greatly to teams.”

Supply Chain Coordinator, Remagin Etex Ireland.

After his employer re-located to the UK, Deivid opted to stay in Ireland and wait for a new opportunity. Enter Remagin Etex Ireland (at the time Horizon Offsite Ltd.). While a General Operative, Deivid covered every element of on-floor operations, including assembly, roll forming, insulation and site work. But what really took his interest was stock taking.

“I am motivated by the clear organisation of things. I offered to help in supply chain because I wanted to help build a clear process that works. I found designing systems to be something I really enjoy; I created the first Purchase Order tracker in the company, as well as the first estimations for stock plans.”

Supply Chain Coordinator, Remagin Etex Ireland.

Etex provided training through supply chain courses to support Deivid’s work and aid his transition into a new Supply Chain Coordinator position. Deivid’s experiences as a General Operative, alongside this formal training, have been “invaluable”.

Long term, Deivid’s dream is to step up to management and build Remagin’s own supply chain and purchasing department, to further improve the organisation’s ability to supply clients with quality products.

Vasyl Pylypiv works in one of the most cutting-edge roles in construction – 3D concrete printing. As a 3D Construction Printing (3DCP) Operator for HTL.tech, Vasyl's role encompasses a number of tasks. This includes interpreting technical drawings to ensure accurate print geometry, managing material handling for a consistent supply of concrete mix, operating the batch plant and pump system to control material flow, and accurately recording production outcomes for quality assurance and traceability.

Beyond these core tasks, Vasyl is also responsible for conducting routine maintenance and troubleshooting with the printer and associated systems, and calibrating equipment for print precision. The work requires operating within a controlled additive manufacturing environment, adhering to national and international standards for 3D construction printing and local Irish building regulations.

Coming to Ireland from Ukraine, Vasyl shared how his role in MMC has transformed a career marked by working in a physically and psychologically demanding sector.

“I have previously worked on oil rigs in Siberia and I worked away from home for 30 days at a time. Since coming to Ireland and joining HTL.tech, I now work hours that allow me to be home every evening and spend weekends with my family. It also allows me time to do other things and study more to advance my career.”

3D Construction Printing (3DCP) Operator, HTL.tech

Vasyl’s Bachelor's degree in Well Drilling and experience on oil rigs as an engineer and in quality control made him a strong candidate for the 3DCP Operator role. His hands-on background in high-pressure, technically demanding environments translated well to 3D construction printing, where precision, mechanical understanding, and problem-solving are essential. After hiring him, HTL.tech organised 10 weeks of intensive training to bring Vasyl up to speed in operating and maintaining the machinery.

Looking ahead, Vasyl wants to share his skillset with others in the construction sector:

“Since joining HTL.tech, I have completed Levels 1 and 2 of the COBOD accredited training in 3D construction printing. I'm currently doing my final level training, which will allow me to be recognised as a certified COBOD trainer.”

3D Construction Printing (3DCP) Operator, HTL.tech